|

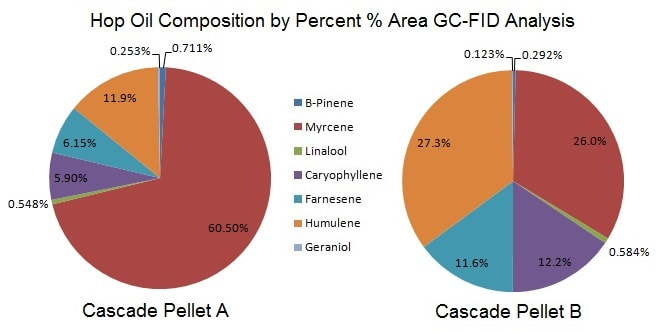

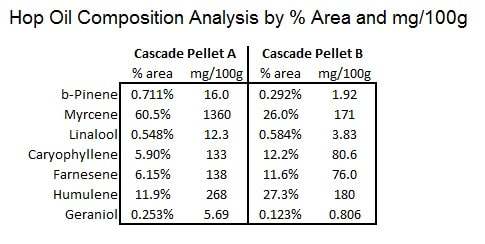

After meeting and listening to many Brewers this year, it became obvious, the importance of hop aroma quality has never been greater than it is today. Aroma quality evaluation has been classically considered the hand-rub analysis. Each year Brewers gather to evaluate the annual harvest using this technique. Where we are today.... Laboratory analysis can accurately determine the total hop oil content by steam distillation, a portion of the oil can be analyzed by Gas Chromatography (GC). This GC data provides a break-down of the 5-7 most common compounds found in hop oil. Additional techniques such as: GCMS, headspace, SPME, SBSE, and more, are used to further define hop aroma. Yet, with all of our technology, nothing seems to effectively grasp the evaluation of aroma quality. Furthermore, there are currently no techniques that allow a Brewer to accurately calculate hop oil additions or substitutions. What is the problem.....? At AAR, we propose a shift in the focus of laboratory aroma evaluation. The classic data used to describe hop aroma found in varietal catalogs, product labels, and so on, is not only confusing, but flawed. This classic approach uses the GC results in terms of the "% area" of a "peak" to determine the content of various hop oil components. One major difficulty with % area revolves around the fact that when one component disappears or is absent, the others appear to increase or be in greater than expected concentrations. When comparing this type of data to the "typical" ranges for a variety it becomes difficult to interpret. See Figure 1. Figure 1. Comparing the % results of these two Cascade pellet samples, one can see where the loss or absence of myrcene in Sample B results in higher than expected results for the other components. Why? The total of this data needs to add up to 100%, remove some of one component, all others now make up a slightly larger proportional slice of the pie. We Have a Solution......! ASBC Hops - 17 outlines an alternative technique to the "% area" approach and work at AAR Lab has begun to evaluate as many varieties as possible. This technique is much more quantitative, and also provides data that just makes more sense. We propose adding the units of (mg/100g) of hops in addition to % area to all of our Aroma Quality data. See Table 1. below for the new data format used in evaluating Aroma Quality. Table 1. The addition of the (mg/100grams) data clearly illustrates the improvement made in the interpretation of the Cascade Pellet data. Some very interesting results have been discovered studying single hop varieties grown in different regions. Where does this go from here...?

At AAR we are expanding our aromatic profiles to include many more compounds. In addition, we will be providing more comprehensive Aroma Quality (AQ) certificates of analysis (C of A's) in 2019. By providing this new perspective on Aroma Quality we are hopeful that we can contribute to a greater understanding of hops including: proper drying & preservation techniques, a tool for Brewers to find and replicate recipes, new and more accurate varietal specification ranges, and the identification of regional and seasonal differences in aromatic qualities. Cheers, Zach Update 6/2019 - We have two Aroma Quaility Packages Available for 2019!!!

6 Comments

|

AuthorZach Lilla, Lead Chemist at AAR has over 17 years of analytical chemistry experiece focused in the areas of Food, Dietary Supplements, Beer, Wine, Hops, and Distillate Analysis. Archives

August 2022

Categories |

Don't Like the Shopping Cart?

|

RSS Feed

RSS Feed