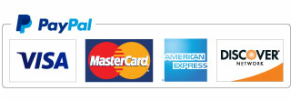

How do I know when my hops are ready to harvest? Determining the timing of harvest is difficult, many different techniques are used including lupulin gland color, smell, cone size, and moisture. Yet, none of these techniques are completely fool-proof. Harvest too early and your crop may not meet the quality standards for either oil or alpha content for the particular variety. Having good analytical data is a definitive indicator of the “ripeness” of the hop cone. Growing location, weather, soil, and a variety of other factors can affect the harvest timing. In addition, each variety will mature at different times, often referred to as early, mid, or late season varieties. The general relationship to alpha content, total oil, dry matter and quality of hops over time is demonstrated in figure 1. This relationship will be slightly different for each variety and each growing location. There are three main pre-harvest testing techniques that are most often used. First, hops used for bittering are tested for “alpha & beta acid content” when they are suspected of being ripe. You can then refer these values to the standards of A/B content for your particular variety. Secondly, crops that will be sold for aroma qualities, “total oil content” is tested to evaluate the content versus the variety standard. Lastly, “moisture/dry matter” can be used as the sole indicator of harvest timing. By using these pre-harvest testing techniques, you can be sure that harvest occurs at the peak of quality. In addition, for growers with many different varieties, it allows you to prioritize and schedule your harvest. At AAR we include free moisture/dry matter results with all pre-harvest acid or oil tests. This just makes sense, the moisture content is critical to the correct calculation of your results, so why not make this process consistent and as accurate as possible. Alpha & Beta Acids – Role in Brewing Alpha acids are responsible for the bittering of beer. While boiling the wort, hops are added, heat results in a conversion (or isomerization) of the alpha acids into the more water soluble iso-alpha acid form, which in turn, allows them to be more readily dissolved into the wort. Typically, the longer the hops are boiled, more alpha acids are transformed and ultimately, the more bitter the beer. As a side note, hops with low cohumulone content are reported to yield brews with a “smoother” bitterness profile. In addition, you have probably seen IBU’s or (International Bitterness Units) on a chalkboard at your local pub. At AAR, we perform the ASBC method Beer-23, which is the basis for these values. Another very important role of alpha acids is their antiseptic quality. By adding hops, beer is preserved and remains fresh. Although, care must be taken to prevent iso-alpha acids from reacting with light which can cause a skunky smell. This is why most beer bottles are brown or green. Beta Acids also play a role in brewing, adding some bitterness and having beneficial antiseptic qualities. It is important to note they do not isomerize, but rather oxidize during the boil. Although not fully understood, they may also play a major role in aged or dry-hopped beers. When reviewing your results, the beta acid content and the ratio of the alpha/beta content can also be good indicators of variety or cone maturation.  HPLC Lab at AAR HPLC Lab at AAR

Alpha Acids Testing

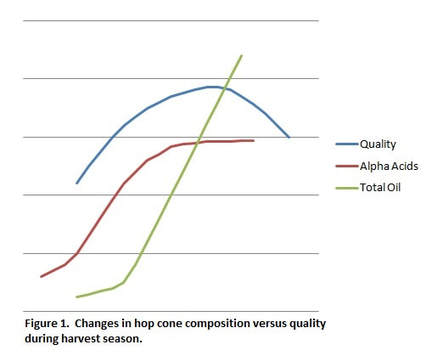

There are two standard ASBC (Association of Brewing Chemists) methods of analysis that are currently offered, Hops-6A Alpha & Beta Acids in Hops by Spectrophotometry, and Hops-14 Alpha & Beta Acids in Hops by HPLC (International Method). I will refer to these by either SPEC or HPLC for the remainder of this article. When conducting either of these tests there are three main alpha acid compounds that are analyzed: cohumulone, humulone and adhumulone, and three main beta acid compounds: colupulone, lupulone and adlupulone. The SPEC test uses a spectrophotometer, these instruments have been around since the 1940’s and subject a sample of the hop extract to specific wavelengths of light. The amount of light that is “absorbed” when passing though the sample has a fixed relationship with the amount of alpha or beta acids. This test is not able to distinguish or quantify the individual acids.

HPLC or High-Performance Liquid Chromatography hit its stride in the 1970’s and is now the workhorse of the modern analytical lab. HPLC first “injects” a portion of the sample into a liquid stream which pumps the sample through a steel column or tube filled with sand-like particles. Under high pressure, and the interaction of the sample with these particles, the alpha and beta acids are separated. They continue to flow through a “cell” where a special spectrophotometer is used to detect the compounds. This technique has many advantages by avoiding interferences and quantifying individual acids through this “separation” process.

HPLC vs SPEC Typically, a pre-harvest alpha acid lab “SPEC” or spectroscopy test run by ASBC method HOPS-6A will include a total alpha/beta single value, not corrected for moisture. The SPEC method is designed for testing dried or pelletized samples, and it struggles to effectively extract fresh samples due to their high moisture content. High moisture content also causes an unstable reading of the sample and often requires duplicate analyses averaged to ensure the results are close. The SPEC test uses no standard reference material; results are solely based on the accuracy of the instrument being used. The optics and light sources of these instruments deteriorate over time, and unless it’s properly qualified and maintained, can yield results with significant error. The ASBC round robin testing does not provide help in evaluating the accuracy of fresh wet hops analyzed by SPEC. Based on these factors, the SPEC test is really only suited for post-harvest analysis of dried hops or pellets, where it still has many disadvantages when compared to HPLC. At AAR, for pre- & post-harvest, we recommend the HPLC alpha & beta acids test, which now includes values for HSI (Hop Storage Index), % alpha acids, % beta acids, % cohumulone, % colupulone, dry matter and moisture. This internationally accepted test has many advantages over the SPEC test including; use of an external qualified standard reference material, a “phase” extraction with an aqueous/solvent system much better at dealing with “wet” samples, greater precision & accuracy, and cohumulone/colupulone content helps identify variety specific characteristics. In addition, we report the values at 10% moisture and provide the acceptable alpha/beta ranges for your sample. Some individuals also use HSI, dry matter, A/B ratios in combination with the % alpha to predict harvest timing. Obtaining this information for your varieties year after year can help create a much better understanding and provide a valuable record to be referenced moving forward. Dry Matter/Moisture Testing Dry matter is basically the (Total Weight - Moisture) of a hop cone sample. As the hop cones mature dry matter increases and conversely the moisture content decreases. Dry matter is a good technique that can be done to monitor the maturation of your crop. Depending on the growing region and variety the target dry matter ranges from 21-28% or a moisture content of 79 – 72%. Dry matter typically increases 1-2 % per week during the harvest season. Typical lab tests will require you to pay more for a moisture test or determine the moisture yourself. Moisture testing is a time consuming process and food dehydrators are not capable of fully drying samples. This can add significant error to your results, and just simply compounds the confusion when trying to calculate your results at 10% moisture. Consistency in the moisture analysis technique here is key. Try our Hop Calculator and you will see how small changes in the moisture and alpha values have a large effect on the values at 10% moisture. These 10% results are critical, as they are the values you will compare to varietal standards when verifying your crop quality and ripeness.

At AAR, we provide a free dry matter/moisture analysis with any Acid/Oil test. We want to provide you with the most consistent and accurate data. The harvest timing is critical to the quality of your crop, why sacrifice the quality of the testing technique? Again, try the hop calculators; small errors in moisture, alpha, or oil content here are magnified when calculating the values at 10% moisture. Post-processed moisture content of pelletized or whole cone hops is another important aspect to consider. A target range of 8 - 12% (sometimes higher for whole cone) is the general consensus. Dried too much the hops will crumble, leave too wet and they are subject to mold. Check out our hop calculators for tools to aid you in accurate tuning of your oast.  4 of the 9 hop distillation systems at AAR 4 of the 9 hop distillation systems at AAR

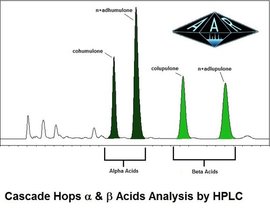

Essential Oil – Role in Brewing The essential oil within hops is where all the great aroma and flavor comes from. The role of aroma in brewing has increased significantly due to dry-hopping, the term used to describe any hop additions to wort after cooling, or beer during/after fermentation. All sorts of devices and techniques are being developed to impart aroma into beer. Brewers adjust recipes in regards to the amount of oil in hops. In addition,the aromatic profiles of hop varieties are very important when trying to consistently impart these flavors in beer. Providing the total oil content, as well as the GC (Gas Chromatography) profile of your hops allows brewers to verify the aroma quality. In addition, much importance has been placed on the regional differences in hop aroma, borrowing from the French term terroir - in reference to grapes. At AAR, we are developing advanced techniques to evaluate terroir and learning how to utilize these techniques for marketing and quality purposes.

Essential Oil Testing

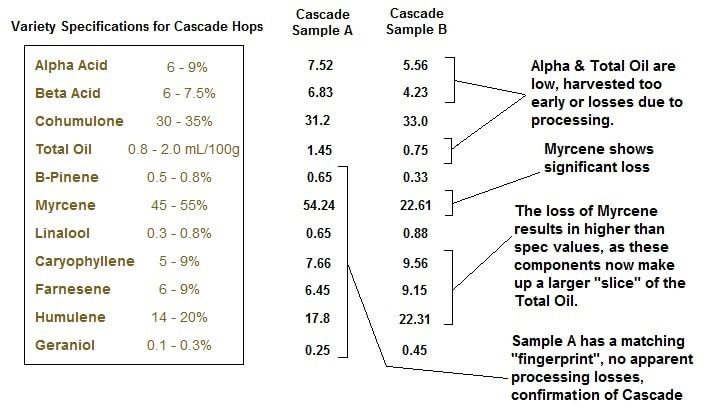

At AAR we analyze pre- or post-harvest samples by the industry standard ASBC Hops-13, Total Essential Oils in Hops by Steam Distillation. This test specifies the use of a rather complicated apparatus, in which we have carefully tuned and refined our technique. Through our study of this process we have ensured that elimination of losses due to heat degradation and the proper collection of the fragile hop oil volatiles has been achieved. As a hop plant matures, the alpha acid content levels off, yet oil content continues to rise. This is why many growers have a tendency to harvest too early before oil content has reached the desirable levels. At AAR our pre-harvest oil test includes results for total oil content mL/100g, moisture, dry matter, oil content values at 10% moisture, and acceptable ranges for the variety being tested. Pre-harvest oil testing is recommended when your customers are purchasing hops for their aromatic qualities. The specific aroma profile of your pre- or post- harvest sample can also be evaluated by analyzing a portion of the oil by GC (Gas Chromatography). At AAR our GC method is based on ASBC Hops-17, which is the industry standard when it comes to evaluating quality. The GC aroma profile also reveals the variety specific “finger print” of your hops. This is another layer of quality by ensuring your customer that they are receiving the correct variety. Our results match well against many published varietal specifications (as the same technique was used to obtain their data). GC aroma testing includes the Total Oil mL/100g, and the % of beta-pinene, myrcene, linalool, caryophyllene, farnesene, humulene, and geraniol.

HSI – Hop Storage Index

Hop storage index was developed in the 1970’s to yield information on the quality and storage potential of a particular variety. When hops react with oxygen, a degradation or oxidation of the hops occurs. To monitor this process, hops are ground and extracted with a solvent. A portion of the solvent is treated and measured at two different light wavelengths. As the oxidation progresses the adsorption of light at 325nm decreases and increases at 275nm. So, when looking at the ratio of the two values A275/A325, some general indicators of quality can be inferred. HSI <0.25 - Very Fresh <0.31 - Freshly picked 0.31 – 0.40 - Normal range for processed or stored hops 0.40 – 0.50 - Aged hops 0.50 – 0.60 - Old Hops At AAR, we include the HSI result with either the HPLC or SPEC assay. The HSI can also be used to predict loss of alpha acids, various approaches are used but due to the significant amount of variables, it is not without significant error. To adjust utilization rates or observe losses directly under your storage conditions, a HPLC test can be run to obtain the exact values. Oxygen, heat, and light are the hops enemy, so keep this in mind when storing your crop.

I have my crop harvested, dried to the target moisture, how can I let customers know I have a quality product?

While pre-harvest testing has helped you target the harvest timing, test results can also aid in establishing a baseline of your crop before any processing or drying has occurred. In addition, this data can be used for marketing the sale of your wet fresh hops. Pelletizing and drying can cause significant losses of both oil and acids. By looking at the A/B or oil content, pre- vs. post- one can adjust temperatures, timing and parameters to optimize their hop processing. Alternatively, one can simply rely on the post-processing evaluation of the crop, figure 2. Whether dried whole cone or pellets, the certification of your crop is essential in achieving successful sales. Providing your customers with a comprehensive certificate of analysis (C of A) containing the alpha/beta, HSI, total oil, & GC aroma profile has many advantages over your competition. Brewers can adjust their recipes to accommodate seasonal variability, identify the variety’s aromatic fingerprint, and trust that the product has been evaluated correctly for quality.

0 Comments

Your comment will be posted after it is approved.

Leave a Reply. |

AuthorZach Lilla, Lead Chemist at AAR has over 17 years of analytical chemistry experiece focused in the areas of Food, Dietary Supplements, Beer, Wine, Hops, and Distillate Analysis. Archives

August 2022

Categories |

Don't Like the Shopping Cart?

|

RSS Feed

RSS Feed